Inside the

Tailoring House: Our Story

Boglioli's history is deeply rooted in the early 1900s, when the Boglioli family first tried their hand at the world of men's tailoring in the picturesque Italian town of Gambara, located in the province of Brescia.

By the 1960s, after garnering a well-established reputation and extensive know-how in the art of tailoring, Boglioli decided to share its valuable craftsmanship experience and started to produce suits for other fashion houses.It wasn’t until 1973 that the Boglioli brand was born. It offered an innovative proposal that blended classic, masculine elements with cutting-edge techniques, such as the deconstructed jacket and a unique garment-dyeing approach.Boglioli did not just create garments but redefined the concept of luxury in the jacket world. It was the first brand to introduce a fully deconstructed jacket to the market, defying the conventions of the time.

However, the real innovation lay in the company’s ability to transform a 1980s process – initially designed to reduce production costs – into a unique and exclusive method for dyeing fine and delicate raw materials, such as wool, cashmere, and silk.

The Fabric Warehouse

True craftsmanship means combining the best traditional materials with the latest technology. A jacket's character is initially defined by the choice of fabrics, patterns and colours. The fabric is the first chapter of the story that any jacket, once worn, will tell. This department is primarily entrusted to store all the materials needed to produce garments. It is divided into three sections: winter fabrics, summer fabrics, evergreen fabrics, components and related trimmings.

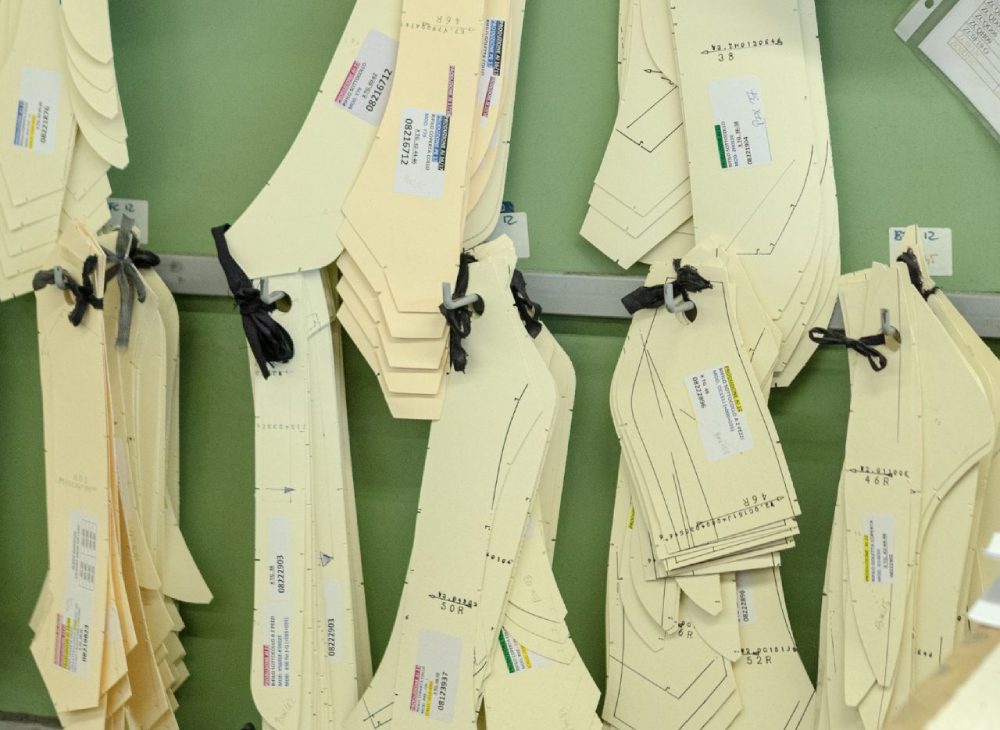

The pattern department

Art and meticulous precision come together to make the garment patterns; this is the first step involved in the making of a Boglioli garment. A jacket concept is expressed not only via the fit but also the attention to detail.

Cutting

Each garment is cut with precision and care. Once the fabric is cut, the Boglioli jacket can be brought to life. Attention and consideration are at the heart of the entire garment-making process; pinpoint precision is required for this quite literally hands-on job.

Sewing

Boglioli tailors convey their expertise in all the steps that bring a suit or jacket to life. A passion for handcrafted work is the best expression of Boglioli's tailoring art; details that require due care are now sewn by hand. Various types of sewing machines are used to attach the different garment components, depending on their specific applications. A buttonhole sewing machine is needed to make buttonholes in a garment.

Pressing

The aim of pressing is to bestow a precise shape and texture on the garment in question.

This is the last step. From here, the jacket will pass through the quality control department to check that everything has gone according to plan and detect any anomalies. The jacket is now finished.